By Julliane Silveira, scientific journalist, São José dos Campos, SP, Brazil

The carbon-carbon composite, also known as Carbon Fiber Reinforced composite (CFRC), form a class of materials with very particular applications in aerospace areas (BOKROS; LAGRANGE; SHOEN, 1973), such as aircraft breaks and rocket nozzles manufacturing. The main features that justify its application are maintenance of mechanical properties at temperatures above 1300 °C, low density, chemical inertia, dimensional stability and low thermal expansion coefficient (MURDIE, 1993; SAVAGE, 1993). Due to its good tribological properties and its very low thrombogenicity, pyrocarbon is also largely used in biomedical materials, such as heart valves (BOURRAT, et al., 2006).

The carbon-carbon composite manufacturing process generally uses synthetic resins and gases (like methane and propane) as well as other precursors. However, the use of petrochemical precursors in several countries, such as Brazil, requires compliance with specific laws related to work safety. As they are carcinogens, they require additional high wages to the worker, as well as the supply of individual and collective protective equipment, including risk of major accidents due to the high flammability characteristic of the precursor.

Another important point is the matter of waste disposal of the process that shall be in compliance with the environmental legislation of each country.

In this context, it is necessary to carry out studies to seek alternatives for the development of this type of composite, in order to generate less environmental impact and reduce the risk to the people involved in the process. The attempt to use a vegetable carbon precursor looks interesting and possible.

For this reason, researchers from the Brazilian Instituto Tecnológico de Aeronáutica (ITA) studied the use of vegetable precursors, such as soybean oil and ethanol, for the development of this type of composite. The results are presented in the article “Fast densification process in manufacturing carbon / carbon using vegetable precursors”, published in the current issue of the Journal of Aerospace and Technology Management (Vol. 10).

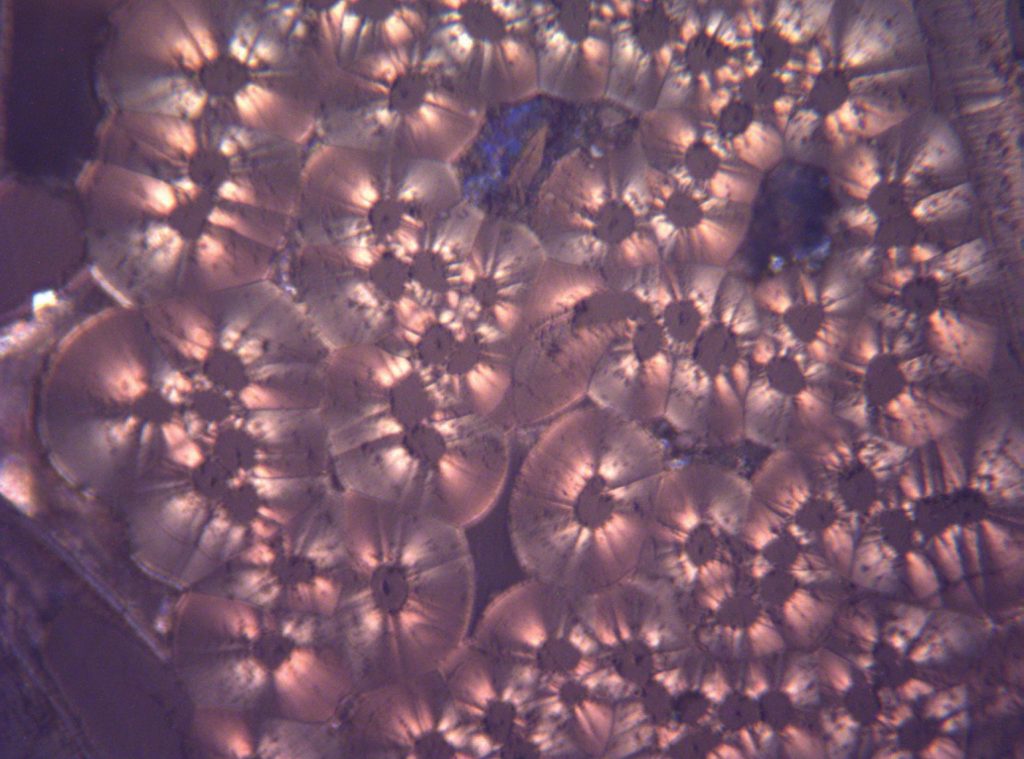

Figure 1. Microscopy with white polarized light of hexane samples densified at 1200 °C

Figure 1. Microscopy with white polarized light of hexane samples densified at 1200 °C

“Carbon precursors for carbon-carbon parts are expensive, so it’s important to look for alternative precursors,” explains Inacio Regiani, who is responsible for the study and researcher at ITA.

This product is often used in the aerospace industry. “The main use of this kind of material is the rocket nozzle and aircraft brakes,” says Regiani.

The study points out that vegetable oils have proven to be good for carbon-based composites and fabrication and could be further investigated for use on a large scale. Today, the process is not yet economically viable.

“There are other technologies being studied and made available, in a controlled way, to cheapen the manufacturing process of composites,” explains Regiani.

References

BOKROS, J. C., LAGRANGE, L. D. and SHOEN, F. J. Control of structure of carbon for use in bioengineering. In: WALKER JUNIOR, P.I. and THROWER, P.A. (ed.) Chemistry and physics of carbon. New York: Marcel Dekker, 1973.

BOURRAT, X. Low temperature pyrocarbons: a review. J. Braz. Chem. Soc. [online]. 2006, vol. 17, no. 6, pp. 1090-1095, ISSN: 0103-5053 [viewed 28 November 2018]. DOI: 10.1590/S0103-50532006000600005. Available from: http://ref.scielo.org/nfw46n

MURDIE, N. Carbon-carbon matriz materials. In: BUCKLEY, J.D. and EDIE, D.D. (ed.) Carbon-carbon materials and composites. New Jersey: Noyes Publications, 1993.

SAVAGE, G. Carbon-carbon composites. London: Chapman & Hall, 1993.

To read the article, access it

SANTOS, J.J.S. and REGIANI, I. Fast Densification Process in Manufacturing Carbon/Carbon Using Vegetable Precursors. J. Aerosp. Technol. Manag. [online]. 2018, vol. 10, e2718, ISSN: 1984-9648 [viewed 28 November 2018]. DOI: 10.5028/jatm.v10.921. Avaliable from: http://ref.scielo.org/f7cdv9

External link

Journal of Aerospace Technology and Management – JATM: <http://www.scielo.br/jatm>

Como citar este post [ISO 690/2010]:

Recent Comments